CONNECTED magazine n°7

LEMO opens a new facility in the Netherlands to strengthen its services

To support the unprecedented growth of its Benelux business, LEMO has invested in a new, purpose-built, hi-tech and eco-friendly facility near Amsterdam.LEMO opened its Dutch subsidiary in 2005 initially to cover the Benelux market. Meanwhile, its staff grew from 2 to over 50 people. Today, LEMO Netherlands has a cable assembly department as well and is home to the LEMO European Distribution Centr

LEMO now showcases its product line on EPLAN Data Portal

The EPLAN Data Portal is an integral part of the EPLAN drawing platform, which enables users to significantly reduce effort & engineering time, and also to easily generate the detailed and accurate documentation that is required by today’s end users of automation systems.EPLAN Data Portal contains a wide library of CAD components: over 900’000 data sets from more than 290 manufacturers.

LEMO receives Directindustry i-NOVO awards at Hannover Messe

During Hanover Messe 2016, LEMO participated in the Directindustry i-NOVO awards. Out of 25 nominees, two LEMO products got 1st and 3rd place in the Design and Tech categories respectively.

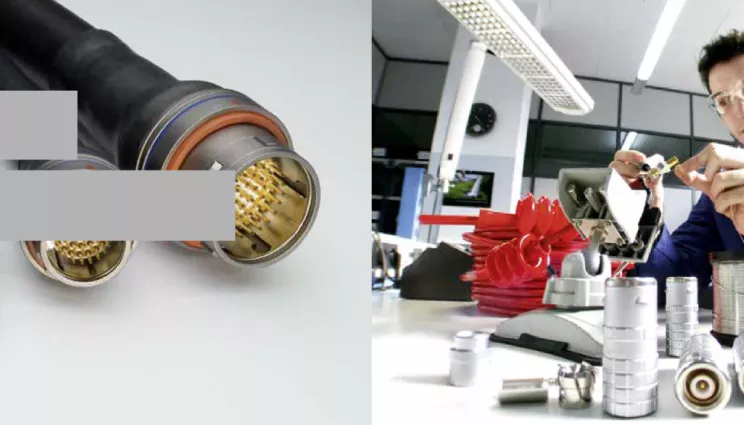

Beyond connectors

LEMO’s long experience and solid expertise in the field of connector and cable assembly has now beenextended by offering complete interconnection solutions.

Sculpteo: the success of a factory in the cloud

"There began to be a lot of talk about 3D software,3D objects and 3D printing in 2009” explains Clément Moreau, co-founder of Sculpteo. “For us, it was a new revolution in the history of industry. So we started to get ready for when the big wave would arrive…”

Printing an exact copy of the patient

In the printer are two polymer materials owned by 3D Systems: the material which will “hold” the finest elements and the building material itself. Once it's printing, the machine super- poses – one by one – layers 32 microns deep.